Ford had a record-breaking recall year. Here's how it plans to fix quality

Published in Business News

Ford Motor Co. ended a record-breaking recall year with 152 notices to consumers in 2025 concerning safety issues or product defects requiring repair. But executives say quality costs are improving.

The Dearborn, Michigan, automaker nearly doubled the record previously set by General Motors Co. of 77 recalls in 2014, according to the National Highway Traffic Safety Administration's recall tracker. From faulty parking modules that create the potential for rollaways to risks of parts detaching from SUVs to notices that an electrical short may create conditions for a fire to spark, issues have run the gamut. And those cost the automaker time, money and reputation among consumers.

"I would like the consumers to know that we stand behind our products," Kumar Galhotra, Ford's chief operating officer, said in an interview with The Detroit News. "Our initial quality has improved substantially this year, and if something does go wrong with their vehicle, I want them to know that we will act promptly to take care of it."

Stellantis NV reported 53 recalls in 2025. GM was fourth in recalls with 27, according to NHTSA, behind RV manufacturer Forest River.

The recall totals are a sign of the Blue Oval's prioritization of quality, safety and warranty cost reductions, Ford executives said. Over the past two years, the company doubled its safety team to find and fix problems, and now it is testing critical systems to failure. Initial quality for products rolling off the line in 2025 is among Ford's best ever, according to internal data, said Josh Halliburton, Ford's executive director of quality.

But for customers, recalls can come with frustrations. John MacLellan, 37, an attorney in Jacksonville, Florida, faced challenges with buying a Mustang Mach-E this summer after the automaker ordered dealers not to deliver the electric vehicles due to a lockout issue.

"They text me that they'll get the keys ready, and then I hear nothing, and I hear nothing," MacLellan said about reaching out to a dealer to buy the SUV. "I see the news on Reddit. It makes you a little leery that it could theoretically trap a kid inside."

Ford last month also cited cost improvements in its announcement to raise its 2025 adjusted operating earning guidance to about $7 billion. That was up from $6 billion to $6.5 billion it stated in November, though still would represent a more than 30% decrease from 2024 following the advent of President Donald Trump's tariffs, supply chain disruptions, the expiration of the federal plug-in vehicle tax credit and consumer sentiment deterioration. Ford will report annual financial results on Feb. 10.

Galhotra declined to provide financial specifics, citing the company's blackout period ahead of reporting earnings, but said costs have improved for multiple quarters now and part of that is quality and warranty.

"Our warranty costs are going down," he said, "and that's obviously directly related to improving initial quality of the vehicles that we're selling, and improving the cost of repairs, and lowering the repairs for vehicles already in customers' hands."

Last year's recalls included about 40 reissued related to software. An audit found the company didn't have a robust way of ensuring the software was in the right place. The effort was to ensure the software had been installed correctly.

Increasingly, recalls are able to be fixed with over-the-air updates. Nonetheless, dealers like Jim Seavitt, owner of Village Ford in Dearborn, said their service departments regularly have full-day schedules of addressing recalls. Meanwhile, dozens of new vehicles sit on the lot, unable to be delivered because they need a fix.

"They’ve taken a lot of what could be customer-paid work, and they don’t pay that well," Seavitt said of the impact of the recall repairs on his business. "It used to be: 'Quality is job one.' Somewhere, they lost that."

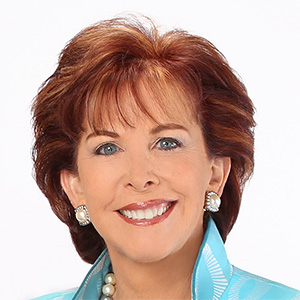

Consumers weigh dozens of matters in a decision to buy a vehicle, including recalls and repairs, said Stephanie Brinley, S&P Global Mobility's AutoIntelligence principal automotive analyst. They can forgive a mistake, but how an automaker addresses the problem is what really makes a difference.

"Some people get a bunch of recall notices and don’t think it's important and don’t do anything about it," she said. "Having a ton of recalls looks bad, but on the other hand, it's how well it’s handled from the consumers’ perspective — how quickly, how well or how efficiently."

Recalls also aren't the only way to assess quality. Automakers regularly release fixes, especially over-the-air updates, that aren't safety-related. Issuing those repairs, however, shows how a company is standing behind its product, said Sam Fiorani, vice president of global vehicle forecasting at AutoForecast Solutions LLC.

"The screens and hybrids and all the different technology that has gone into every vehicle today ... there are going to be stumbles along the way," he said. "Ford might be showing all of its issues, whereas other manufacturers probably haven’t displayed problems that they’re likely having. Ford, being family-owned, they’re not going to let the lawyers take care of everything."

According to an analysis by DeMayo Law Offices LLP, however, Ford was the top brand to be involved in class action lawsuits between 2020 and 2025. A study from automotive search iSeeCars.com looking at more than 30 years of recalls between 1985 and 2016 found Ford in that timeframe was the least proactive in issuing recalls.

Ford has increased its monitoring for quality problems, Galhotra said. But ultimately, it doesn't matter from where an initial indicator of a problem comes, but that the automaker is in a position to address the issue, he said.

Galhotra illustrated the complexity of addressing software bugs: A driver simply opening the vehicle door, sitting down, turning on the vehicle and putting their seatbelt on creates all sorts of scenarios.

"Someone might get in the vehicle after opening the door in 100 milliseconds. Somebody might do that in 500 milliseconds," he said. "Somebody might turn on the radio first. Someone might put on the seatbelt first.

"You have to develop software validation tools," he continued, "that can simulate that sequence millions and millions of times to make sure that there isn't a bug where in one particular case, at one particular sequence, it's going to cause an issue."

Third-party product testing has validated Ford's claims of improved quality. Ford scaled Consumer Reports' brand reliability ranking, finishing at No. 11 in the top half of all brands included, up from No. 22 the year prior. It was its best placement in the past 15 years. Lincoln was No. 20.

In an overall ranking that includes owner satisfaction, road-test rating ranking and safety, Lincoln was the top-ranked Detroit Three brand at No. 7. Ford was No. 18. Jake Fisher, Consumer Reports' director of testing, described the recent innovations on new Fords as "really, really impressive."

Likewise, in J.D. Power's 2025 Initial Quality Study that looks at consumers' first 90 days of ownership, the Ford brand had more top finishers in their respective segments than any other, though General Motors Co. as a company had the most top-ranked vehicles.

Still, the IQS scores for Ford and luxury brand Lincoln overall fell below the industry average. J.D. Power's dependability study looks at owners' experience after three years. Ford and Lincoln were also below average there, but they were the most improved brands.

The company has also updated its software validation processes. It's leveraging artificial intelligence and machine learning to detect issues sooner, as well. Shoring up manufacturing operations, adding camera systems and implementing plant-specific targets for process improvements are also ways in which Ford is seeking to improve quality.

When the process of making changes to address Ford's quality problems began, the sources were spread about fairly evenly between issues in design, manufacturing procedures and supplier processes, Galhotra said. The breakdown has moved over that time as Ford has split its teams between hardware and software, conducted audits and increased the use of data to identify problems.

"Those are the three big areas," Galhotra said, "we've been really, really deep into, multiple strategies that include processes, tools, people, to make sure that the designs are robust, make sure the suppliers are supplying high quality products and making sure our manufacturing facilities are not adding any error states into the vehicles that we ship to our customers."

©2026 www.detroitnews.com. Visit at detroitnews.com. Distributed by Tribune Content Agency, LLC.

Comments